3 Things To Think About When Installing Your New Generator

So, you’ve gone through the process of selecting a vendor, mapping out your specs, and placing an order for a new generator for your data center. Now that the manufacturing is complete and it's on its way, you might think the hard part is over, but that may not be the case. Let’s take a look at generator site installation.

A well-planned generator installation includes assessing power capacity to meet both current and future demands, selecting an appropriate location with adequate space and ventilation, and choosing the right fuel type for efficiency and environmental impact. Data center operators must also consider complying with local regulations to avoid legal issues and ensure safe operation. When installing, planning for future expansion and integrating the generator seamlessly with existing power infrastructure, such as UPS and ATS systems, is also key. By addressing these factors upfront, data centers can avoid costly disruptions and maintain seamless operations during power outages.

Beyond this typical checklist, let’s look at some of the lesser-known factors, trends, and considerations that affect generator installation.

Installing vs. Servicing: A Timing Question

When selecting a backup power generator for a data center, it’s easy to get caught up in the convenience of transport and installation. A unit that arrives in fewer pieces or requires minimal crane time can seem like the obvious choice. However, long-term serviceability is just as important — if not more so — than ease of installation. A generator that’s easier to install but harder to maintain can create costly challenges down the road, especially when unexpected repairs arise.

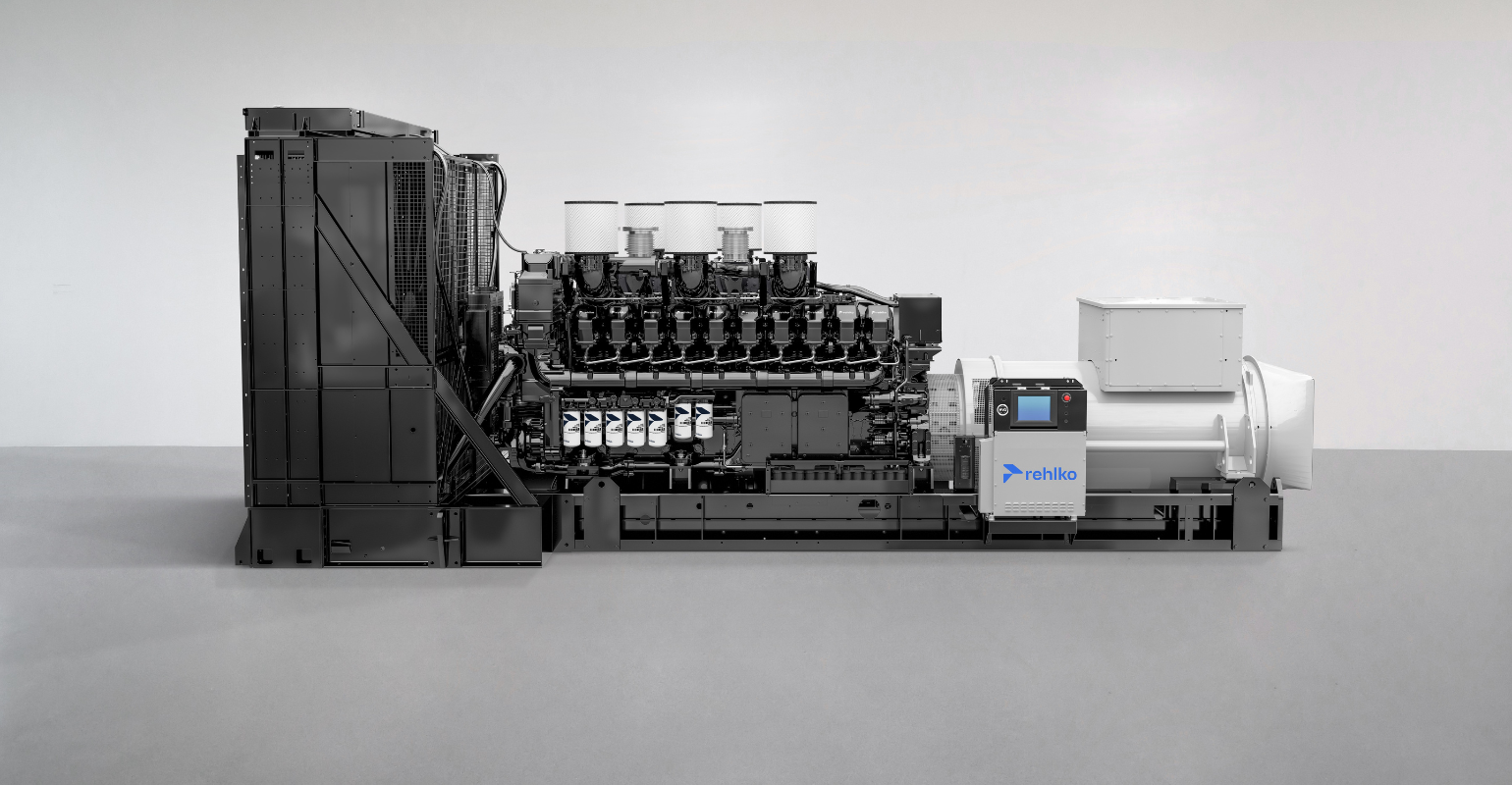

Take the Rehlko eFRAME as an example. Unlike some configurations that ship the genset and enclosure as a single unit, we deliver the tank, genset, and eFRAME enclosure separately. While this may require a slightly more involved installation, it brings significant long-term advantages. First, the freight savings can be substantial, by eliminating the need to ship the generator to a third-party packager and instead shipping in three optimized splits, our customers often cut freight costs by half or more. Second, there’s no added waiting period after generator production, since we don’t rely on external packagers to build around the unit — our in-house team manages everything, reducing total lead time. Most importantly, the same engineers who design our generators also design the enclosures, ensuring consistency, durability, and integrity across the entire system.

Our internal silencer design further reduces complexity, eliminating extra field installation steps and improving serviceability over the life of the unit. While some competitors compress internal space to streamline shipping, doing so can make more involved repair work difficult and time-consuming. A little extra effort up front creates a more maintainable, cost-effective system down the road.

Racking and Stacking: Not Just For Servers Anymore

When planning a data center backup generator installation, one emerging trend to keep an eye on is stacked or racked generator configurations. These setups are gaining popularity, particularly in space-constrained environments where maximizing footprint efficiency is crucial.

- In a stacked configuration, one generator is placed directly on top of another, with the lower unit engineered to bear the load.

- A racked configuration positions multiple generators within a steel framework, similar to shelving, where each unit is independently supported. While these designs have been around for some time, they’re becoming more common in high-density urban areas like Singapore, California and Northern Virginia, as well as in regions where site layout presents unique challenges.

The rise of AI-driven workloads and increasing power densities in data centers are likely to further accelerate the adoption of these configurations. As backup power requirements grow, facility operators need flexible solutions that optimize both space and reliability. If you’re evaluating generator enclosures for a project where space factors are troublesome, considering racked or stacked configurations could help streamline installation and improve long-term operational efficiency. Whether it’s a necessity for your specific site or a forward-thinking move to prepare for future demand, an approach to backup power deployment like racking or stacking may be a planning effort that becomes more popular in the future.

Enclosure Customization

Customizing your data center backup generator enclosure is crucial to ensuring a seamless installation and smooth operation. In this regard, one of the most important considerations is cable entry: that is, how and where power cables are routed into the enclosure. The overall cable management structure plays a significant role in determining the efficiency and organization of the system. Does the facility have an onboard switchboard, outdoor switchgear, or no switchgear at all? Each scenario requires a tailored approach to ensure proper connections and functionality. Planning for these elements in advance helps avoid last-minute modifications that can delay deployment or increase costs.

Accessibility is another key factor. The placement of doors and access points in relation to other units can impact maintenance efficiency and overall usability. Clear access ensures data center operators can reach all necessary components without obstruction, which is critical for ongoing servicing and emergency repairs. Additionally, site-specific modifications — such as sound attenuation and structural adjustments — may be necessary to meet noise regulations or prevent operational issues. For example, some facilities require an extended exhaust plenum to disperse hot air away from sensitive cooling equipment, preventing thermal buildup that could impact chiller performance. Designing the generator enclosure in conjunction with the overall site plan, rather than as an afterthought, ensures a fully integrated system that operates efficiently and meets all site-specific requirements.

A View For The Future

Although installation seems like the end of the road for a backup power procurement process, incorporating thoughtful planning for both installation and long-term serviceability can save data centers from costly disruptions and maintenance challenges. By considering different trends, configurations, and customizations, gensets and their enclosures can better meet specific site needs, and data centers can optimize both their immediate setup and future-proof their power infrastructure.