Rehlko × Toyota – Powering the Future with Hydrogen

Why Hydrogen, Why Now?

When it comes to backup power, there is no one-size-fits-all solution. At a time when the digital infrastructure industry is facing growing constraints on energy supply and mounting pressure to decarbonize, hydrogen has emerged as one of the most talked-about alternatives to conventional diesel generators. But with hype often outpacing real-world deployment, what makes now the right time to invest in hydrogen?

For Rehlko, the answer is clear: the market is changing, and expectations are shifting. Customers are not just asking for power. They’re asking for cleaner, longer-lasting, and more innovative options that align with their environmental and performance goals. Rehlko is responding with action, developing a new hydrogen generator platform built on Toyota’s proven fuel cell technology to demonstrate that zero-emission backup power can be both practical and high performance. And while diesel remains a reliable workhorse in many scenarios, there is increasing interest in zero-emission technologies that don’t compromise on power or resilience.

That’s where hydrogen steps in.

Listening to the Market

Rehlko’s decision to pursue hydrogen-powered backup systems is not just about innovation for innovation’s sake. It’s about expanding the range of options for mission-critical customers.

In many cases, organizations are seeking lower emissions at the point of use. In others, they are responding to regulatory changes and ESG mandates that require cleaner technologies. Hydrogen generators offer a compelling value proposition here. Unlike batteries, which have runtime limitations, hydrogen systems can run as long as fuel is available. That makes them well suited for backup use cases that demand long-duration resilience, especially when grid interruptions are unpredictable or prolonged.

The ability to diversify backup power offerings also gives customers more flexibility when designing systems around performance, compliance, and sustainability needs. Hydrogen becomes another tool in the toolbox, not a replacement for every other solution.

Why Toyota?

Of course, Rehlko didn’t develop this solution in isolation. At the heart of the new system are hydrogen fuel cell modules from Toyota — a company with over 30 years of experience in the field and a commercial track record that speaks for itself.

The Toyota Mirai, a hydrogen fuel cell vehicle launched in 2014, has provided a real-world demonstration of reliability and efficiency. That legacy made Toyota a natural partner for Rehlko’s efforts to bring hydrogen into the backup power space. By leveraging technology proven in mobility and adapting it for stationary use, this partnership helps bridge the gap between innovation and implementation. For industries like data centers that require reliable, scalable, and environmentally responsible backup solutions, it marks an important step toward making hydrogen viable and operationally ready.

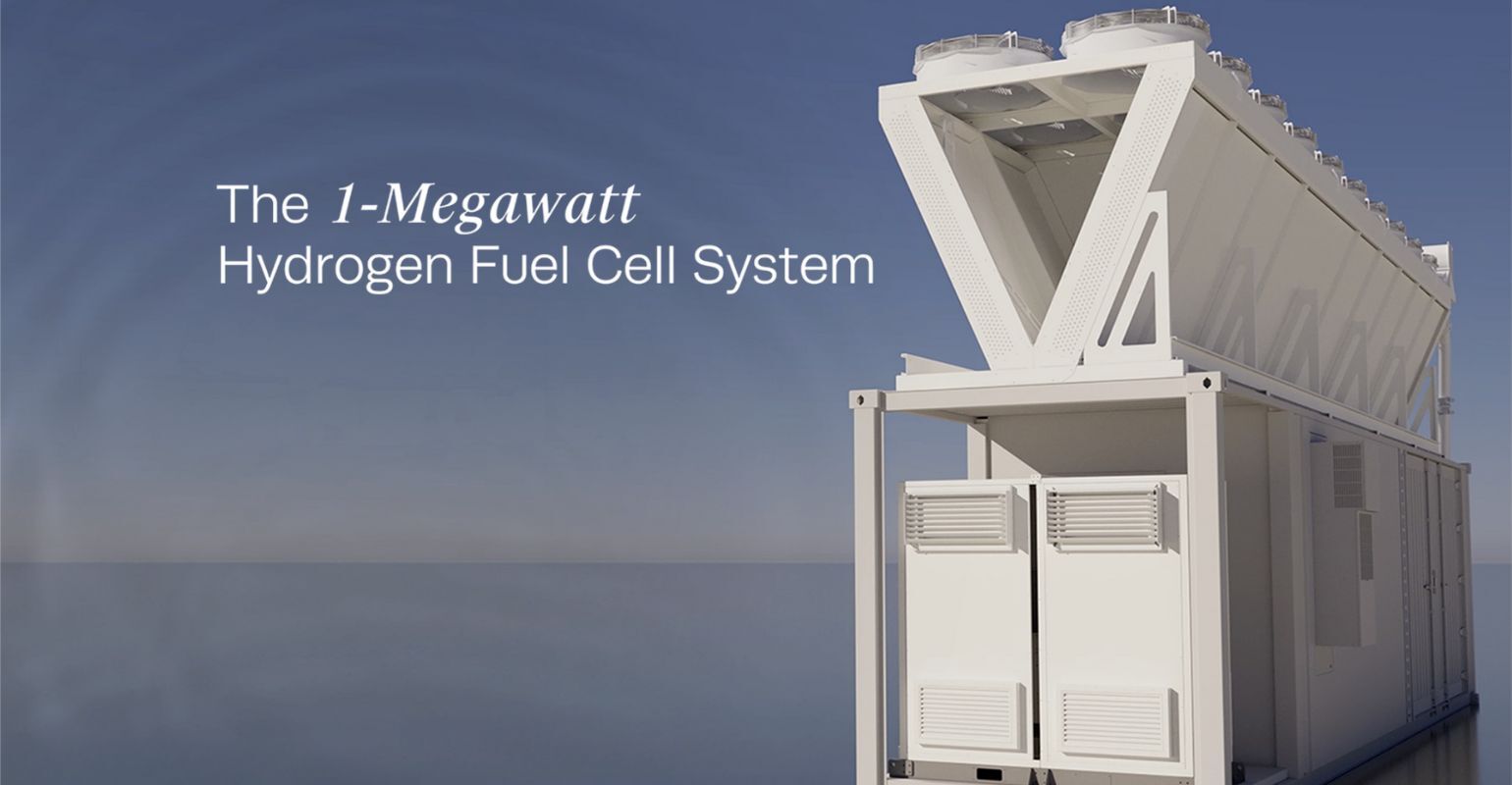

In this case, Toyota supplies the fuel cell modules, and Rehlko provides the rest. The company designed the generator system, integrated the fuel cells, and added all necessary components for power conversion, cooling, and startup. The result is a cohesive, high-performance platform that benefits from both companies' expertise.

Lessons from Klickitat Valley Health

Rehlko’s hydrogen journey isn’t just theoretical. The Klickitat Valley Health pilot provided valuable insight into how zero-emission backup power performs in a real-world, mission-critical setting.

Hospitals demand high uptime and can’t afford failures. The project demonstrated that hydrogen systems can meet those standards while aligning with sustainability goals. It also reinforced the need for dependable performance that mimics the behavior of conventional generators, such as fast start-up times and load-following capabilities.

These are not “nice-to-have” features. They’re table stakes for many of Rehlko’s customers, and the pilot confirmed that hydrogen can deliver.

Hydrogen in Context

It’s important to understand where hydrogen fits into the broader backup power landscape. Rehlko is not positioning it as a replacement for HVO, natural gas, or battery solutions. Each has its place, depending on the application.

What sets hydrogen apart is its ability to provide zero-emission backup power without sacrificing run time or performance. It can be deployed like a conventional generator, offering modularity and scalability, while also supporting longer runtimes than batteries can typically handle.

And in industries like data centers, where power density is increasing and uptime expectations are non-negotiable, that combination is starting to look more and more attractive.

Looking Ahead

Hydrogen isn’t the only answer. But it’s a powerful one.

As the industry continues to adapt to the twin pressures of growth and sustainability, solutions like Rehlko’s hydrogen generator are helping close the gap between operational demands and environmental responsibility.

And for customers who need a high-performance, zero-emission option that works like the backup systems they already trust, now might be exactly the right time to consider hydrogen.